We are awash in "green" articles that highlight examples and best-practices of companies such as Patagonia, Stonyfield Farm, and Timberland—businesses that have had sustainability as part of their DNA from the outset.

But for large multinational brands (especially suppliers of packaged goods) that are dependent on energy-intensive supply chains and high volumes of raw materials, a different approach is often required.

For such brands, the journey to a more sustainable business usually starts with the entry question of "where (or how) do we start?"—particularly in the case of those brands for which, to put it simply, "selling more stuff" (and more than their competitors) has been the prevailing internal mindset and the business priority, up until now.

This article focuses on leading global brands that are making the transition from treating sustainability as a hot "green topic" to embracing it as a true business strategy. It includes US and European companies that have identified "hotspots" in their supply chain where their environmental impact can be reduced, relatively quickly and inexpensively.

Viewed in isolation, some of these steps may seem minor. However, viewed against the total volume of transactions, their cumulative impact is undeniable.

These seemingly small changes are not quick fixes or marketing makeovers but true sustainable strides that have entered the mainstream marketplace. They also reflect successful collaboration between marketing and operations departments that have worked together to implement genuine environmental changes vs. marketing half-truths that consumers are starting not to believe. These brands recognize that sustainability should not be viewed just as a cost saver but also a sales driver, and that products and services embedded with sustainable practices are attracting more publicity and increased brand loyalty—and in many cases they are selling faster.

A common theme that emerges from the examples that follow is the need to challenge old assumptions around products and packaging, and the processes that link them, in order to deliver rule-bending innovation. While it is true that groundbreaking sustainable innovation that results in totally new business models is still rare, it's also true that brands are starting to move along the eco-innovation spectrum and out of the obvious incremental changes such as carbon offsets and recycling programs—toward looking at the total picture and the rich opportunities environmental challenges can create.

The following six examples from M&S, Wal-Mart, UPS, Unilever, Boots the Chemist, and Whirlpool have been selected because each highlights an innovation across a different part of the sustainability spectrum, from design and packaging, to product formulation, to waste and transportation.

Admittedly, some of these innovations, such as the UPS example, emerged initially from cost-savings thinking, with the environmental gains a byproduct of the initiative; but the key, in each case, is that the innovation became a catalyst for the company to think about sustainability differently. All these companies also still have a long way to go to becoming truly sustainable, but they are getting started and the small changes are giving them market wins, increased stakeholder loyalty, and internal momentum to set their sights on much bigger business and brand transformations across their product and service portfolios.

Responsible Packaging: Marks & Spencer's—Looking at the "Whole Package"

The leading UK retailer, Mark's & Spencer (M&S), is making big sustainability strides with its five-year, 100-point "eco" plan called "Plan A" (because there is "no Plan B"). Two of the five key pillars of this plan are "waste" and "sustainable raw materials," both of which have had a big impact on how M&S thinks about the whole picture of packaging.

M&S started simply, by quickly identifying food product "hotspots" where there was excessive packaging that could easily be changed to reduce weight, footprint, and the amount of the materials used—without negating safety, freshness, or quality. It also smartly recognized that the packaging of the product is just part of the picture, and that it is the entire supply chain—from farm to factory to depot to store to a customer's home—that needs to be addressed and considered. For example, minimizing packaging of the product on the shelf may mean more packaging in transit, so that would not be a balanced or real solution. Also, removing packaging may not always be the most sensible solution if unpackaged foods become damaged or rot quicker, because having to discard perished products only creates more waste.

Below are three examples of how small, simple changes have made huge differences to materials usage. Through changes such as these, between April 2007 and May 2008 M&S saved 1,402 tons of packaging (equivalent to 255 elephants) for these three food products alone.

Traditional apple crumble packs were covered by a full paper carton; by changing the sleeve and making the tray container lighter, M&S cut the weight of the packaging 70%.

By removing the tray from the beans package, M&S achieved a 92% reduction in materials.

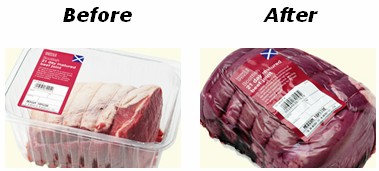

M&S has cut down the packaging weight on its fresh meat products 69% by using a "skin pack" instead of a tray. The new solution also keeps the meat fresher for an additional five days, which means it is less likely to go to waste.

In addition to individual package changes, M&S has replaced most of the cardboard boxes in its supply chain with returnable trays, saving over 27,000 tons of cardboard from going to waste each year.

A smart move M&S has been to be clear and authentic regarding its journey, in terms of where its and how far it has to go. It is transparent around the goals it meets and those that it misses. In doing so, it is bringing its customers along, using the journey to change habits and subsequently building trust in the M&S brand. And the strategy is working not just from an environmental perspective but from a brand and business standpoint as well. Brand loyalty has increased since it launched Plan A, and profits from 2006 to 2007 rose 26%, in an economic climate where higher interest rates, increased personal debt, and reduced consumer spending began to bite.

Transportation Innovation: UPS—"No Left Turn"

UPS famously adheres to a no-left-turn policy by installing technology into its vans that help map out routes that minimize the number of left turns the driver has to take. Avoiding left turns at intersections reduces idling, which in turn lowers fuel consumption—UPS estimates it saves approximately 54.4 million gallons a year. Drivers are also trained to maintain proper air pressure in their tires, drive under 50 mph, and turn off their vans whenever they stop for a delivery, even if just a few seconds. "It seems small, but when you multiply it across 88,0000 vehicles making nearly 15 million deliveries every day during the course of a year, it adds up," according to UPS spokesperson Steve Holmes (UPS press statement, 2006).

According to the company, this simple technique saves a huge amount of gasoline. "In the last year alone, this system has shaved nearly 30 million miles off UPS's delivery routes, saved 3 million gallons of gas, and reduced emissions by 32,000 metric tons of CO2—the equivalent of removing 5,300 passenger cars off the road for an entire year," a UPS release stated, (www.boston.com, April 18, 2008).

If you do the back-of-the envelope math, 3 million gallons saved, at an average diesel fuel price of $2.68 a gallon, amounts to cash savings of approximately $80.4 million.

"No Left Turn" has become a catalyst for UPS to pursue a more rigorous sustainability agenda, including introducing the largest fleet of alternative-fuel vehicles in the entire transportation industry and extensive infrastructure initiatives designed to improve energy efficiency. UPS is becoming a great example of a company with a complex supply chain embracing systems thinking to reassess changes across its value chain.

Product Formulation: Unilever—Let's Concentrate!

With its "Small & Mighty" products, Unilever has doubled the concentration of its Persil and Surf liquid detergents to cut the bottle size in half, bringing a 40% reduction in packaging and a 60% reduction in water usage. (www.sciencedirect.com)

And because the product is smaller, Unilever can also deliver more product per pallet and fit more product on the shelf (200% more) while reducing the number of truckloads required to ship the same number of units by 66%. (https://www.greenbiz.com/feature/2007/08/10/small-packages-have-big-impact)

In adddition, consumers benefit from having a smaller bottle, which is easier to transport and easier to pour from. The environmental benefits of Small & Mighty were promoted by Wal-Mart and helped the brand to grow its sales in the US to $140 million in 2007.

"Small & Mighty" has provided an important easy and first step for many consumers to start to change their habits around using concentrates, and for Unilever it has become an icon for its first step toward creating more sustainable products that address the growing trend among consumers to value "better" over "more."

Design Efficiency: Sam's Club (Owned by Wal-Mart)—One Gallon at a Time

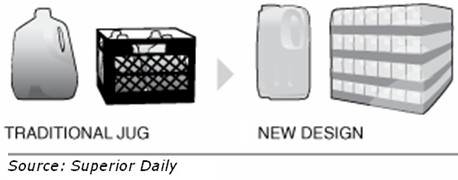

A new boxy milk container design introduced by Sam's Club is cheaper to ship and better for the environment; moreover, the milk is fresher when it arrives in stores, and it costs less.

The new design does away with the need for traditional milk crates. Instead, a machine stacks the jugs into multiple layers with cardboard sheets in-between and binds it all in shrink-wrap (and both materials are recycled after use).

By eliminating crates, Sam's Club estimates that it has cut water use 60-70% (the old crates needed to be washed). Big fuel savings are achieved because no empty crates need to be picked up, reducing trips to each Sam's Club store to two a week, down from five. Energy efficiency is also gained through less refrigeration space—224 gallons of milk can now be stored in the same cooler that used to hold just 80. Customers also benefit from these energy savings. A gallon of milk in the new container now costs 40 cents less.

Wal-Mart is a quickly becoming known as a company working closely with its suppliers to embrace sustainability as fuel for innovation and to collaboratively reach its visionary goals of reaching zero waste and using 100% renewable energy.

Energy Saving: Whirlpool—"Sixth Sense" Green Kitchens

It is estimated that 90% of a household appliance's impact on the environment occurs in the course of its normal use versus during its manufacturing or disposal. Consequently, Whirlpool is putting much of its innovation focus on cutting-edge sustainable solutions that save energy and water during daily use.

Whirlpool's 6th Sense technology adapts work cycles in real-time through smart sensors that reduce the use of water and energy to the quantity necessary to perform their task in an optimal way. For example, Whirlpool's top-loading washer "Knows Every Load": By weighing each load, the machine ensures that it does not use more water than necessary; and its dryer prevents over-drying by sensing when the required drying level is achieved, and automatically stopping.

It's a smart strategy that is easy for consumers to understand and tangible in terms of energy efficiency, and that feels authentic to Whirlpool's heritage of cutting-edge home solutions.

Waste Reduction: Boots The Chemist—Waste Not Want Not

The UK's leading retailer of health and beauty products, Boots The Chemist aims to prevent the generation of waste whenever possible. In 2002–03, it set a target of reducing like-for-like waste for disposal by 20% within five years. By the end of 2005-06, it had achieved a 7.5% reduction—with 47% of its waste currently going to landfill.

Boots The Chemist has done this through waste innovation and small cutting-edge changes across its categories: fully compostable packaging for its sandwiches and reusing the trays used to carry the sandwiches (cost savings of approximately £200,000 a year); and free-standing display units, made from cardboard, that are 100% recyclable (a saving of 83 tons of cardboard and 429 tons of waste diverted from landfill—for total savings of approximately £165,000). The Display Units also flat-pack, meaning that you can get 20 on a pallet instead of 6 (saving in transportation costs of approximately £240,625 a year). Replacing foam board with cardboard makes further materials savings.

Also, 80% of all goods supplied to Boots stores are now delivered without any transit packaging—most of it having been stripped off at the warehouses and distribution centers. Plastic bottles damaged during manufacturing are now recycled, an innovation that diverts 20 tons of waste from landfill. Similarly, Boots diverted 175 tons of "cosmetically damaged stock" from landfill, saving around £22,500 in disposal costs.

From an environmental as well as a cost perspective, the impact of these changes has been impressive. Since 2001/2002, Boots The Chemist's percentage of recycled total waste increased from 37% to 50.5%, delivering a 67% saving in waste-costs.

What is notable about Boots's strategy is that it is not reacting to the issue of the moment but constantly using its brand's power to exert influence on behalf of its consumers.

* * *

Common themes emerge from the examples above that other companies can use to help answer the nagging question: "Where do we start?"

1. Start simple

Some of the answers are pretty simple, and they are probably staring your brand in the face. Identify the "hotspot" in your value chain that you can impact immediately and get a quick win. Be cognizant of distinguishing between an artificial "quick fix" and an authentic small change that is sustainable over the long term.

2. Create an easy first step

Provide consumers with an easy but concrete first step they can take toward more sustainable habits, and educate them on how this action is benefiting the environment and what they can do next.

3. Focus on the journey, not the destination

Be extremely transparent around where you are and where you have to go to reach your sustainability goals. Place more focus on the journey that your company is going on versus end-point claims that can come across as "greenwashing." Talk about mistakes and learnings from them as much as your successes.

4. Be concrete and tangible

Focus on cost and environmental savings that consumers can relate to and which feel authentic to your brand's heritage. Stay away from abstract concepts like "global warming" and "save the planet" that consumers are now desensitized to.

5. Recognize that "Better" is replacing "More"

Ensure that your brand's positioning is evolving with the trend among consumers to value "better" over "more," and the growing awareness that more does not necessarily mean better.

6. Embrace systems thinking

Avoid thinking issue-by-issue or product-by-product. Instead, use systems thinking to reassess the relationship between your different departments, the product relationships across your brand portfolio, and the changes that can be made across the entire value chain (from sourcing raw materials, to consumer use, to waste disposal). This approach will help generate the collaboration and connectedness needed from the outset.

7. View sustainability as an innovation platform

Create a culture where sustainability equals fuel for innovation, not a constraint that is equated with regulations. Challenge old assumptions and pick an innovation focus such as less, simpler, better, cheaper, etc. and ideate off these platforms.